How AI and Robots Help with E-Waste Recycling

Riches are buried under a growing mountain of electronic waste: Last year, an estimated 5.3 billion mobile phones were thrown away – even though they contain many valuable components, such as lithium, aluminum and Indium, a rare metal used in transistors and microchips, for example.

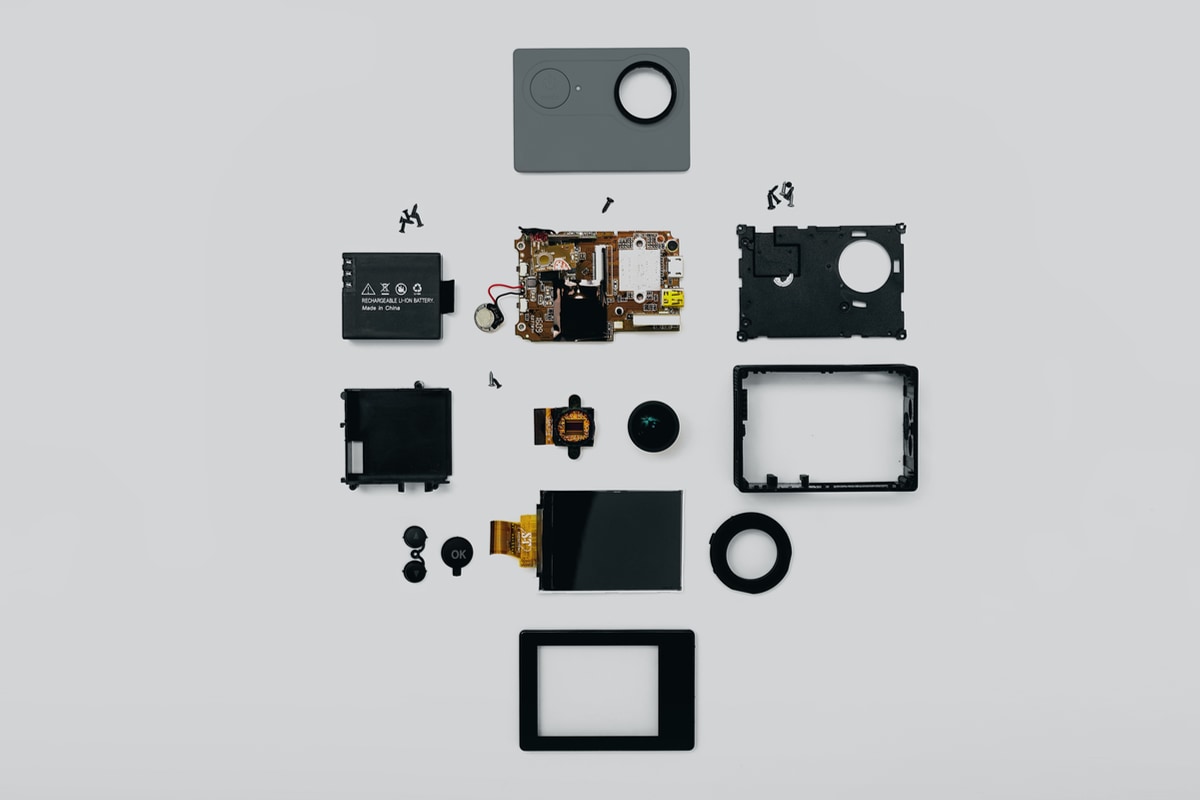

Surprisingly, not even 20 percent of all global e-waste is recycled, according to the ITU. One major reason is that sorting out the mess is really hard. In many cases, old phones, broken microwaves and discarded laptops have to be disassembled by hand – which makes recycling much less profitable.

Now technology is coming to help with the problem it created: thanks to image recognition and advances in robotics, many steps in the recycling process can be automated, Greg Ameyugo explains in our interview. Ameyugo – a speaker at DLD Circular 23 – is Head of Ambient Intelligence and Interactive Systems Division at CEA, the French Alternative Energies and Atomic Energy Commission.

At the recent Automatica Robothon 2023 competition – which was devoted to robotics in the circular economy – a CEA team won a top award for an intelligent image recognition solution.

What’s the best way to reduce electronic waste?

There is no easy way! We are being torn between two currents: on the one hand, the unstoppable spread of the digital world across the physical world – and on the other, the painful realization that the physical world is finite.

The digital world requires an increasing number of data centers, terminals and communications infrastructures. By the end of this year, we will have twice as many devices as humans, and the number is growing exponentially. In addition, the pace of innovation in software and electronics is so fast that many components become obsolete within a year or two.

On the other hand, electronic component shortages, material restrictions and the ever-increasing impact of the digital world on the planet are all warning signs that should drive us to a more reasoned use of digital technologies.

Apart from a paradigm shift, which could take many forms – but most are undesirable, there are two things we can do today: the first is to increase the durability of electronics, and the second, to improve the circularity of electronic components and the systems where they are embedded.

How can technology itself help?

Artificial intelligence and robotics are already deployed in many parts of the electronics design and manufacturing chain. The application that I find most fascinating is the use of robotics and AI to facilitate the circularity of electronic-based systems.

The integration of artificial intelligence capabilities allows robots to deal with “less-than-perfect” situations: things that are not exactly where they should be, shapes that are not exactly as we expected – and at the end of their lives, that is exactly what products look like: deteriorated.

Before this revolution, which is taking place right now, most products had to be disassembled by hand – often in third world countries, with poor working conditions. And in many instances, the logistics and labor costs meant that recycling was simply too expensive to consider.

AI and robotics can help us to have a better grasp on the physical world – literally. Robotic grasping is in fact one of the frontiers crossed by the AI and robotics revolution. And in doing so, we reduce the time, cost and logistics footprint associated with the disassembly of products, opening the way for new circular business models.

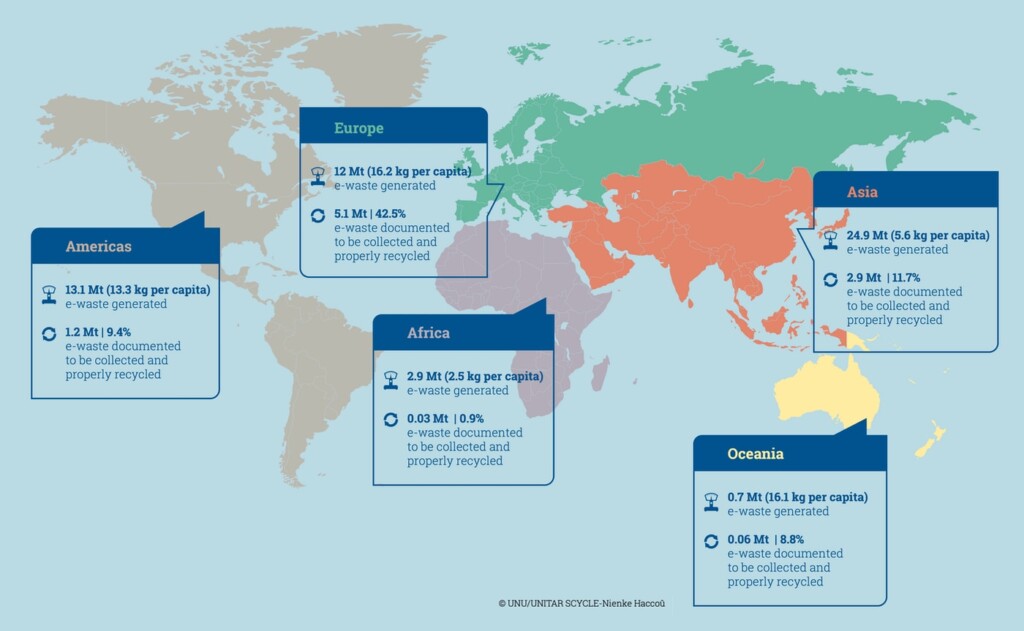

Unhealthy growth: By 2030, every person on the planet is expected to generate 8 kilograms of electronic waste, according to the latest Global E-Waste Monitor by the ITU.

How do we balance technological progress with sustainability goals?

This is a very delicate equation: on the one hand, digital technologies provide opportunities to improve the physical world. They also allow connectivity at lower energy, moving bits instead of atoms.

But the digital continent weighs heavier and heavier both in terms of materials, and energy. Training foundation models can produce more CO2 than 5 Diesel cars in their lifetime. Even a short conversation with ChatGPT requires a large amount of energy – and cooling water for the electronics. If we take the combined carbon emissions of YouTube and Netflix, we produce more CO2 than the entire aviation industry.

The use of materials for electronics is not sustainable either. And the scarcity of rare metals has become a key geopolitical issue. There is some hope in terms of materials substitution – and a lot of research is being done in that direction. But innovation is also taking place on the software side: for example, by advancing the responsible use of AI – frugal techniques, transfer learning, model distillation.

What can corporate leaders do to make their manufacturing more friendly to people and the planet?

Seize the opportunity! My team is working with several major companies that are deploying demanufacturing and circular economy approaches for complex, high-value systems. In many areas of the world, pilot lines are being deployed to improve recyclability. The important notion to keep in mind is that we are at a tipping point. Technology is advancing so fast that what seemed impossible a year ago is now within reach.

Regional differences: Europe and Oceania produce the most e-waste per person, Asia in total. Source: Global E-Waste Monitor 2020.

Where do you see Europe’s role in all of this?

Europe has a key role to play in helping the global economy move towards more circularity. The global manufacturing economy is underpinned by European-designed and built machines, systems and production lines. In fact, when we launched EIT Manufacturing in 2019, our motto was “made BY Europe”, meaning that we believe that the right role to play for Europe is providing sustainable manufacturing technologies to be used anywhere in the world. Wherever products are manufactured – or demanufactured.

My dream is that circular economy demanufacturing lines will spread from Europe to the rest of the world. But we are by no means the only player, so the race is on!

Which opportunities does this transformation offer to early adopters?

Early adopters of automated demanufacturing can expect increased resilience and a better connection to their customers. We have shown this year that AI-enabled robots are moving into the realm of human capabilities for many tasks, and the cost of doing so is coming down fast, so economically sustainable circular business models are within reach.

Find Out More About the Circular Economy

Why the Circular Economy Is the Future