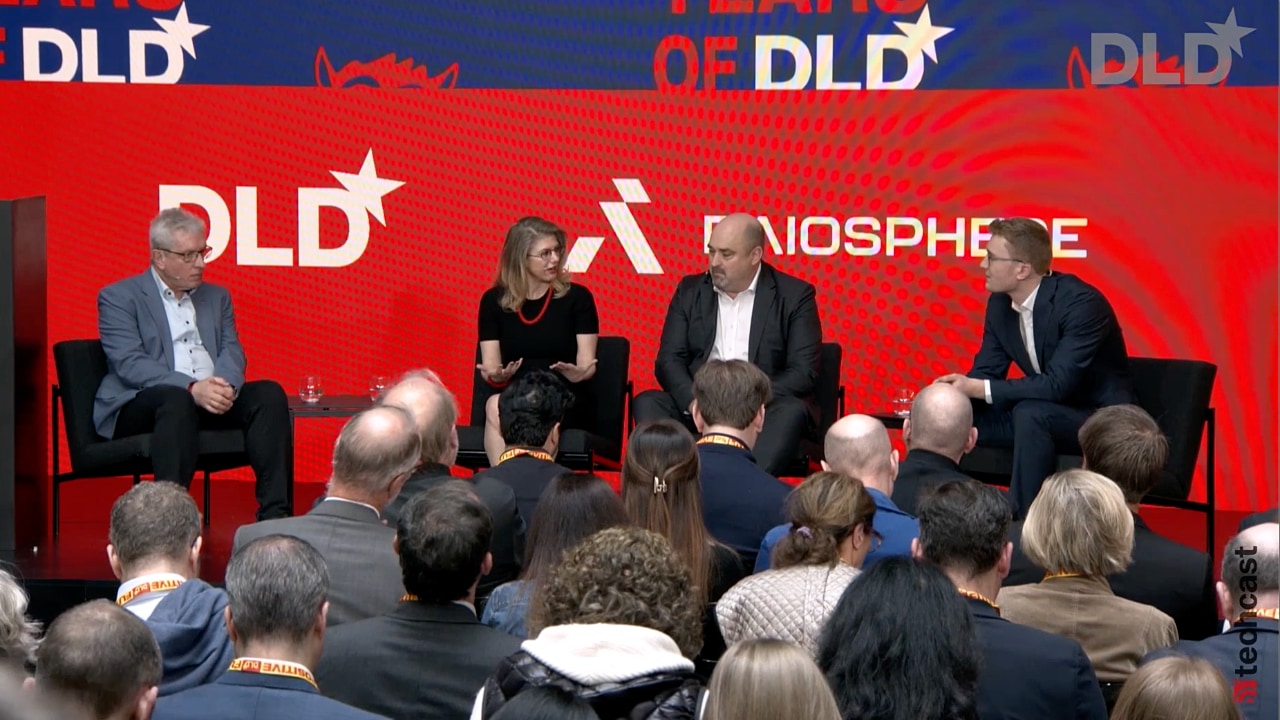

How is artificial intelligence transforming industrial automation? This DLD25 panel discussion, moderated by Deborah Berebichez of EY, brings togethger Wolfram Burgard (University of Technology Nuremberg), Nathan Gruber (Datagon AI), and Sebastian Seitz (EPLAN) for expert insights.

The conversation highlights that applying AI to manufacturing still faces challenges in adoption. Many industrial companies hesitate to roll out AI in factories “because AI is not perfect, we all know this”, Wolfram Burgard notes, and “every second that you lose in a production process” comes at a high cost.

Sebastian Seitz agrees. “When you’re setting up a factory or a production line you’re happy when it’s operating the way it should operate”, he observes, “and you better not touch it anymore because there are so many things working together.”

Still, there are many promising applications where AI promises to dramatically improve efficiency. The oil giant Shell, for example now uses drones and AI to inspect oil rigs, Deborah Berebichez points out. “Instead of taking four to five years to check an oil rig and the pipelines for leakages, now they take three to four months with this advancement”, she says.

Nathan Gruber shares an example from the automotive industry that illustrates how AI can help analyze production problems “and then figure out what was the root cause”.